Why counter flow heat exchangers are more efficient

It is common knowledge amongst heat exchanger designers that a counter flow heat exchanger installation is more efficient than the parallel flow alternative, but for everyone else it can be a bit of a mystery. In this article we will explain what counter flow is and why it is more efficient than parallel flow.

What is counter flow?

First we need to understand what the differences are between counter flow and parallel flow. As a brief description; the term refers to the relationship between the flow directions of the hot and cold fluids. With parallel flow the fluids are travelling through the heat exchanger in the same direction where as a counter flow installation will have the fluids flowing against each other in opposite directions.

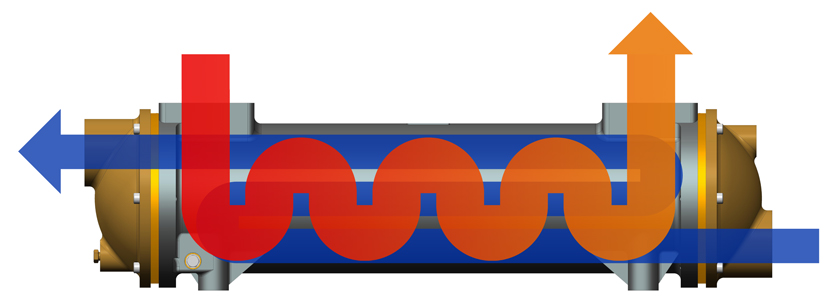

Counter Flow Heat Exchanger

The diagram above shows a Shell and Tube Heat Exchanger. In the counter flow setup, the fluids are travelling along the heat exchanger in opposite directions. On the diagram above the cold fluid, highlighted in blue, is travelling right to left where as the warm fluid, shown in red and amber, travels left to right. This distributes the heat more evenly across the heat exchanger and allows for maximum efficiency. In theory, the cold fluid can exit the heat exchanger at a higher temperature than the temperature of the hot fluid outlet, although in reality this is very difficult to achieve.

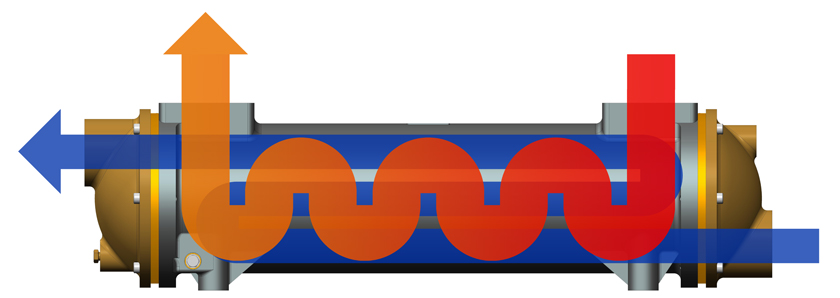

Parallel Flow Heat Exchanger

In a parallel flow setup, both the hot fluid and cold fluids are travelling in the same direction as each other. On the diagram above they both flow from right to left. This will still cool the hot fluid down by a considerable amount but is not as efficient as the counter flow system.

The benefit;

The amount of efficiency gained by using a counter flow system depends on several factors including the flow rates and temperatures (these affect the efficiency on their own) but it will be most noticeable in a larger cooler.

With one of our smaller coolers, such as the 2542 (5" diameter x 600mm long) the effect on performance may only be 1 or 2% but with a larger cooler, such as our 2862 model (8" diameter x 1727mm long) the performance can be 10% greater when using a counter flow installation. At Thermex we always design coolers with a counter flow configuration so it is important to install the heat exchangers correctly. More information about how to install a heat exchanger can be found in our installation, operation and maintenance manual.

For advice or more information about our heat exchangers, please contact us; sales@thermex.co.uk

- Richard O'Connor - Thermex Ltd